processing of large size steel plate test block-欧洲杯在线买球平台

with the increasing of china's comprehensive national strength, the country has carried out many large-scale super projects and projects, followed by the need for steel companies to provide ultra-large specifications, ultra-high strength steel for project needs. like the aircraft carrier currently being built by the country, it is necessary to lay super-large specifications and ultra-high strength steel plates. for example, in the process of natural gas pipeline design and construction in china, expanding pipe diameter, increasing pressure and upgrading steel grade is the development trend of further improving the transmission capacity of natural gas pipelines, which requires steel plates to meet the above requirements at the same time, from shaan-beijing first-line pipe diameter of 660mm, design pressure of 6.4mpa, pipe x60, pipe x60. to the west first line pipe diameter 1016mm, design pressure 10mpa, pipe x70, and then to the west second line, west third line pipe diameter 1219mm, design pressure 12mpa, pipe x80, and then to the china-russia east line natural gas pipeline under construction using a pipe diameter 1422mm, pressure 12mpa project, china's natural gas pipeline industry has made remarkable achievements in the past 20 years. but all of these need large specifications, high-strength steel plates as a support, national steel companies are also doing their best to improve product quality to meet the requirements of use.

whether the processed steel plate can be used, but also need to carry out all aspects of the detection, of which the flaw detection is one of the links, if the detection needs to make the corresponding steel plate physical test block to calibrate the large flaw detection equipment.

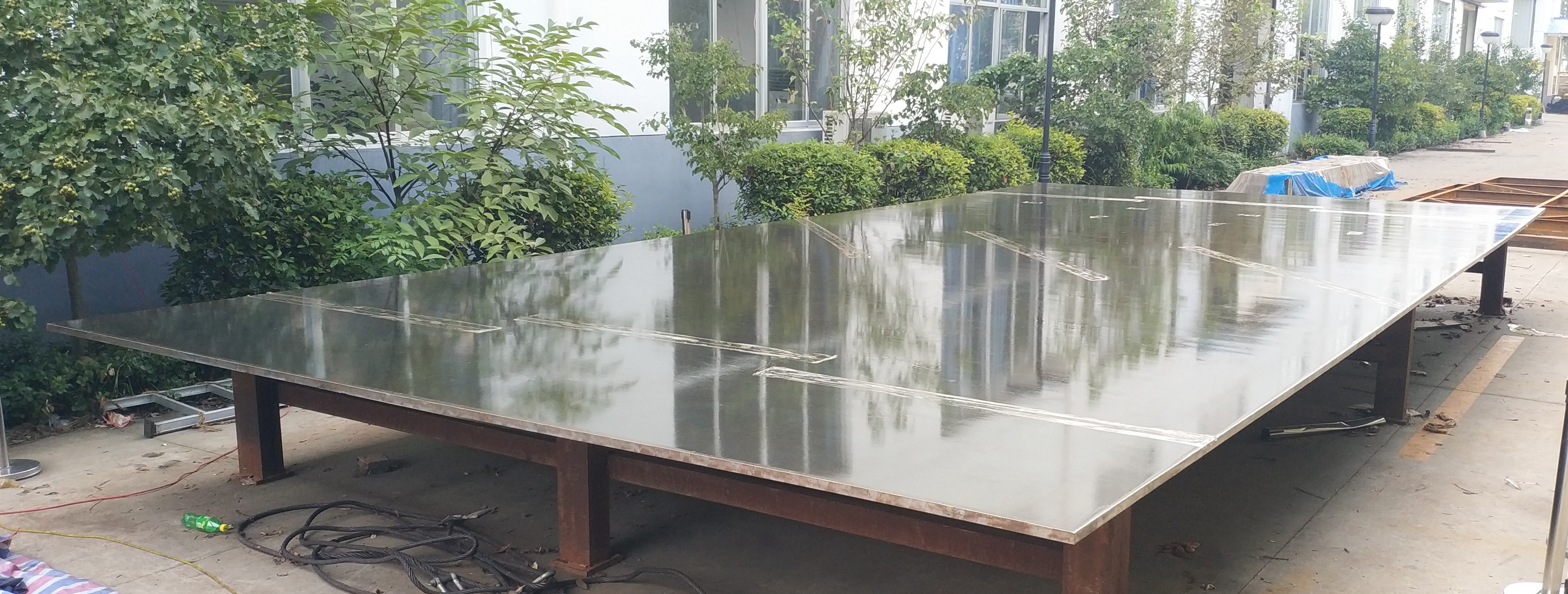

at present, our company has produced and completed the processing of a very large medium and thick plate project for a well-known steel mill in china, and the width of the steel plate test block has reached nearly 5 meters and the length has reached 10 meters, which is the largest single test block in china so far. there are nearly 70 defects in the interior, including hole defects, short-shaped groove defects, long groove defects, etc., the largest long groove up to 2.2 meters, the size requirements for each defect are relatively high, and the entire board will be scrapped, but the construction period is only 30 days, and no problems are allowed in the processing process. it can be said that the processing is very difficult, but at the same time, it is also a test of our company's processing ability. after receiving the production task, our company arranges professional and technical personnel to fully evaluate the entire processing process, rationally optimize the processing technology, and assign excellent technical personnel to supervise the processing throughout the process to ensure the successful completion of the task.

after nearly a month of day and night work, all the defects of large steel plate test blocks have been processed, and all sizes have fully met customer requirements and are ready to be shipped. in the future, it will appear on the automated inspection line to supervise the safety of each large steel plate and make its own contribution to the steel mill. we're proud of you, too.